Technical characteristics

- Metglas amorphous materials C-core

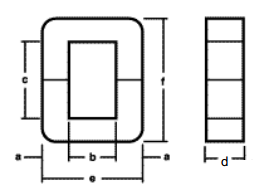

| Core dimension | Performance parameters | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Core No. | a (mm) |

± |

b (mm) ref * |

c (mm) ref * |

d (mm) |

± |

e (mm) |

± |

f (mm) |

± |

lm (cm) |

Ac (cm2) |

Wa (cm2) |

Ap (cm4) |

Mass (g) |

| AMCC 4 | 9.0 | 0.50 | 10.0 | 32.80 | 15.0 | 0.50 | 28.00 | 1.50 | 50.8 | 1.25 | 12.20 | 1.11 | 3.30 | 3.60 | 99 |

| AMCC 6.3 | 10.0 | 0.50 | 11.0 | 33.00 | 20.0 | 0.50 | 31.00 | 1.00 | 53.0 | 2.00 | 12.80 | 1.60 | 3.60 | 6.0 | 154 |

| AMCC 8 | 11.0 | 0.80 | 13.0 | 30.00 | 20.0 | 0.50 | 35.00 | 1.00 | 52.0 | 2.00 | 13.00 | 1.80 | 3.90 | 7.00 | 172 |

| AMCC 10 | 11.0 | 0.80 | 13.0 | 40.00 | 20.0 | 0.50 | 35.00 | 1.00 | 62.0 | 2.00 | 15.40 | 1.80 | 5.20 | 9.40 | 198 |

| AMCC 16A | 11.0 | 0.80 | 13.0 | 40.00 | 25.0 | 0.50 | 35.00 | 1.00 | 62.0 | 2.00 | 15.10 | 2.30 | 5.20 | 11.70 | 248 |

| AMCC 16B | 11.0 | 0.80 | 13.0 | 50.00 | 25.0 | 0.50 | 35.00 | 1.00 | 72.0 | 2.00 | 17.00 | 2.30 | 6.50 | 14.70 | 281 |

| AMCC 20 | 11.0 | 0.80 | 13.0 | 50.00 | 30.0 | 0.50 | 35.00 | 1.00 | 72.0 | 2.00 | 17.50 | 2.70 | 6.50 | 17.60 | 337 |

| AMCC 25 | 13.0 | 0.80 | 15.0 | 56.00 | 25.0 | 0.50 | 41.00 | 1.00 | 82.0 | 2.00 | 19.60 | 2.70 | 8.40 | 22.40 | 379 |

| AMCC 32 | 13.0 | 0.80 | 15.0 | 56.00 | 30.0 | 0.50 | 41.00 | 1.00 | 82.0 | 2.00 | 20.00 | 3.20 | 8.40 | 26.90 | 454 |

| AMCC 40 | 13.0 | 0.80 | 15.0 | 56.00 | 35.0 | 0.50 | 41.00 | 1.00 | 82.0 | 2.00 | 19.90 | 3.70 | 8.40 | 31.30 | 530 |

| AMCC 50 | 16.0 | 1.00 | 20.0 | 70.00 | 25.0 | 0.50 | 52.00 | 1.00 | 102.0 | 3.00 | 24.90 | 3.30 | 14.00 | 45.90 | 586 |

| AMCC 63 | 16.0 | 1.00 | 20.0 | 70.00 | 30.0 | 0.50 | 52.00 | 1.00 | 102.0 | 3.00 | 25.30 | 3.90 | 14.00 | 55.10 | 703 |

| AMCC 80 | 16.0 | 1.00 | 20.0 | 70.00 | 40.0 | 1.00 | 52.00 | 1.00 | 102.0 | 3.00 | 25.40 | 5.20 | 14.00 | 73.50 | 938 |

| AMCC 100 | 16.0 | 1.00 | 20.0 | 70.00 | 45.0 | 1.00 | 52.00 | 1.00 | 102.0 | 3.00 | 25.00 | 5.90 | 14.00 | 82.7 | 1,055 |

| AMCC 168S | 20.4 | 0.50 | 30.0 | 154.20 | 20.0 | 0.50 | 70.50 | 1.25 | 195.0 | 3.00 | 45.40 | 3.35 | 45.80 | 153.2 | 1,101 |

| AMCC 125 | 19.0 | 1.00 | 25.0 | 83.00 | 35.0 | 1.00 | 63.00 | 1.00 | 121.0 | 3.00 | 30.20 | 5.50 | 20.80 | 113.1 | 1,166 |

| AMCC 160 | 19.0 | 1.00 | 25.0 | 83.00 | 40.0 | 1.00 | 63.00 | 1.00 | 121.0 | 3.00 | 28.50 | 6.20 | 20.80 | 129.3 | 1,333 |

| AMCC 200 | 19.0 | 1.00 | 25.0 | 83.00 | 50.0 | 1.00 | 63.00 | 1.00 | 121.0 | 3.00 | 29.80 | 7.80 | 20.80 | 161.6 | 1,666 |

| AMCC 367S | 25.8 | 1.00 | 67.0 | 97.80 | 25.0 | 0.70 | 117.60 | 1.50 | 149.4 | 1.50 | 43.78 | 5.29 | 63.81 | 340.1 | 1,668 |

| AMCC 250 | 19.0 | 1.00 | 25.0 | 90.00 | 60.0 | 1.00 | 63.00 | 1.00 | 128.0 | 3.00 | 31.40 | 9.30 | 22.50 | 210.3 | 2,095 |

| AMCC 320 | 22.0 | 1.00 | 35.0 | 85.00 | 50.0 | 1.00 | 79.00 | 1.00 | 129.0 | 4.00 | 32.50 | 9.00 | 29.80 | 268.3 | 2,167 |

| AMCC 400 | 22.0 | 1.00 | 35.0 | 85.00 | 65.0 | 1.00 | 79.00 | 1.00 | 129.0 | 4.00 | 33.60 | 11.70 | 29.80 | 348.8 | 2,817 |

| AMCC 500 | 25.0 | 1.00 | 40.0 | 85.00 | 55.0 | 1.00 | 90.00 | 1.00 | 135.0 | 4.00 | 35.60 | 11.30 | 34.00 | 383.4 | 2,890 |

| AMCC 630 | 25.0 | 1.00 | 40.0 | 85.00 | 70.0 | 1.00 | 90.00 | 1.00 | 135.0 | 4.00 | 35.60 | 14.30 | 34.00 | 487.9 | 3,678 |

| AMCC 800A | 25.0 | 1.00 | 40.0 | 85.00 | 85.0 | 1.50 | 90.00 | 1.00 | 135.0 | 4.00 | 35.60 | 17.40 | 34.00 | 592.5 | 4,466 |

| AMCC 800B | 30.0 | 1.00 | 40.0 | 95.00 | 85.0 | 1.50 | 100.00 | 1.00 | 155.0 | 4.00 | 39.30 | 21.00 | 38.00 | 794.6 | 5,972 |

| AMCC 1000 | 33.0 | 1.00 | 40.0 | 105.00 | 85.0 | 1.50 | 106.00 | 1.00 | 171.0 | 5.00 | 42.70 | 23.00 | 42.00 | 966.0 | 7,109 |

* Products generally do not fully comply with material characteristics – deviations may occur due to shape and size.